As EDGE Group’s dedicated propulsion systems specialist, POWERTECH plays a pivotal role in advancing the UAE’s sovereign defence capabilities. By designing and manufacturing advanced aerial engines and propulsion systems locally, the company is reinforcing national self-reliance and technological independence.

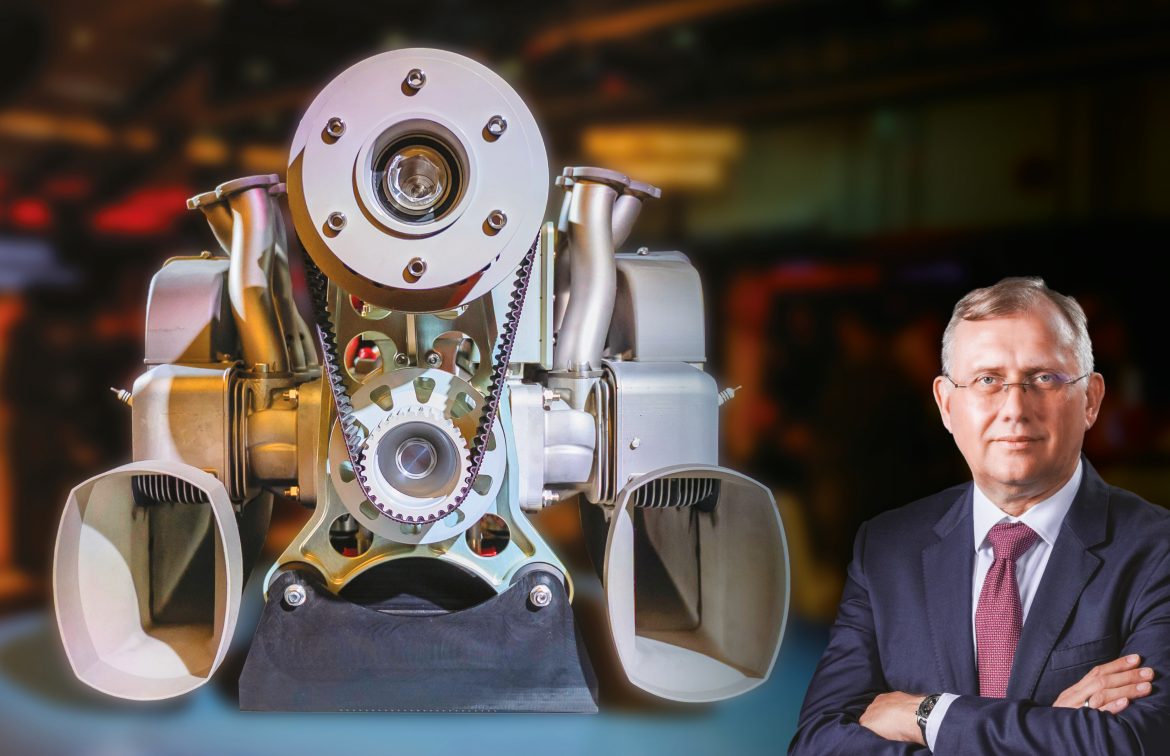

To explore POWERTECH’s contribution to industrial sovereignty and its strategic outlook for the aerospace and defence sector, Al Jundi Journal interviewed Marian Lubieniecki, the company’s CEO, and had the following dialogue with him.

POWERTECH plays a central role in advancing the UAE’s sovereign defence manufacturing capabilities. How does the company’s mission align with EDGE Group’s broader strategy for industrial self-reliance, and what differentiates POWERTECH as the nation’s first propulsion system OEM?

As the UAE’s first propulsion system OEM, POWERTECH was established with a clear mandate: to expand the country’s industrial capabilities by developing and manufacturing world-class propulsion systems for aerospace and defence applications, reducing reliance on external suppliers. This mission is fully aligned with EDGE’s broader strategy to drive industrial sovereignty by building critical capabilities across the defence value chain.

By enabling EDGE to offer complete aerial systems, fully developed, integrated, and manufactured within the UAE, POWERTECH ensures that propulsion is not treated as an isolated component but as a core strategic capability embedded into every platform design. What sets us apart is our full-spectrum, in-country capability, from clean-sheet design to serial production and lifecycle support. We’re not adapting off-the-shelf engines; we’re delivering purpose-built systems optimised for our partners’ specific operational requirements, something traditional OEMs are not always positioned to do. This level of control allows us to accelerate development cycles, mitigate integration challenges, and enable long-term operational sovereignty for our partners.

As a specialist in high-performance aero engines and propulsion systems, which platforms or operational domains are your primary focus, and how do your solutions enhance mission performance in these sectors?

Our primary focus is on powering the next generation of aerial platforms, with an emphasis on unmanned aerial systems (UAS), tactical UAVs, and rotary- and fixed-wing platforms used in ISR, border security, and tactical missions, as well as missile applications. By working closely with our partners across EDGE’s UAS ecosystem, we ensure that our propulsion solutions are tailored to meet real-world mission requirements.

Our systems are engineered to deliver reliable performance and extended endurance in demanding operational environments, enhancing operators’ mission capability while enabling efficient maintenance and lifecycle support. Whether for ISR, logistics, or tactical operations, our propulsion solutions are built to deliver consistent, optimal performance, enhanced fuel efficiency, low maintenance overhead, and adaptability under varied conditions.

This directly enhances operational range, payload flexibility, and mission-readiness across various operating environments.

Can you walk us through POWERTECH’s core areas of expertise, from concept development to design, production, testing, system integration, and lifecycle support, and how these capabilities set you apart from other engine OEMs in the global market?

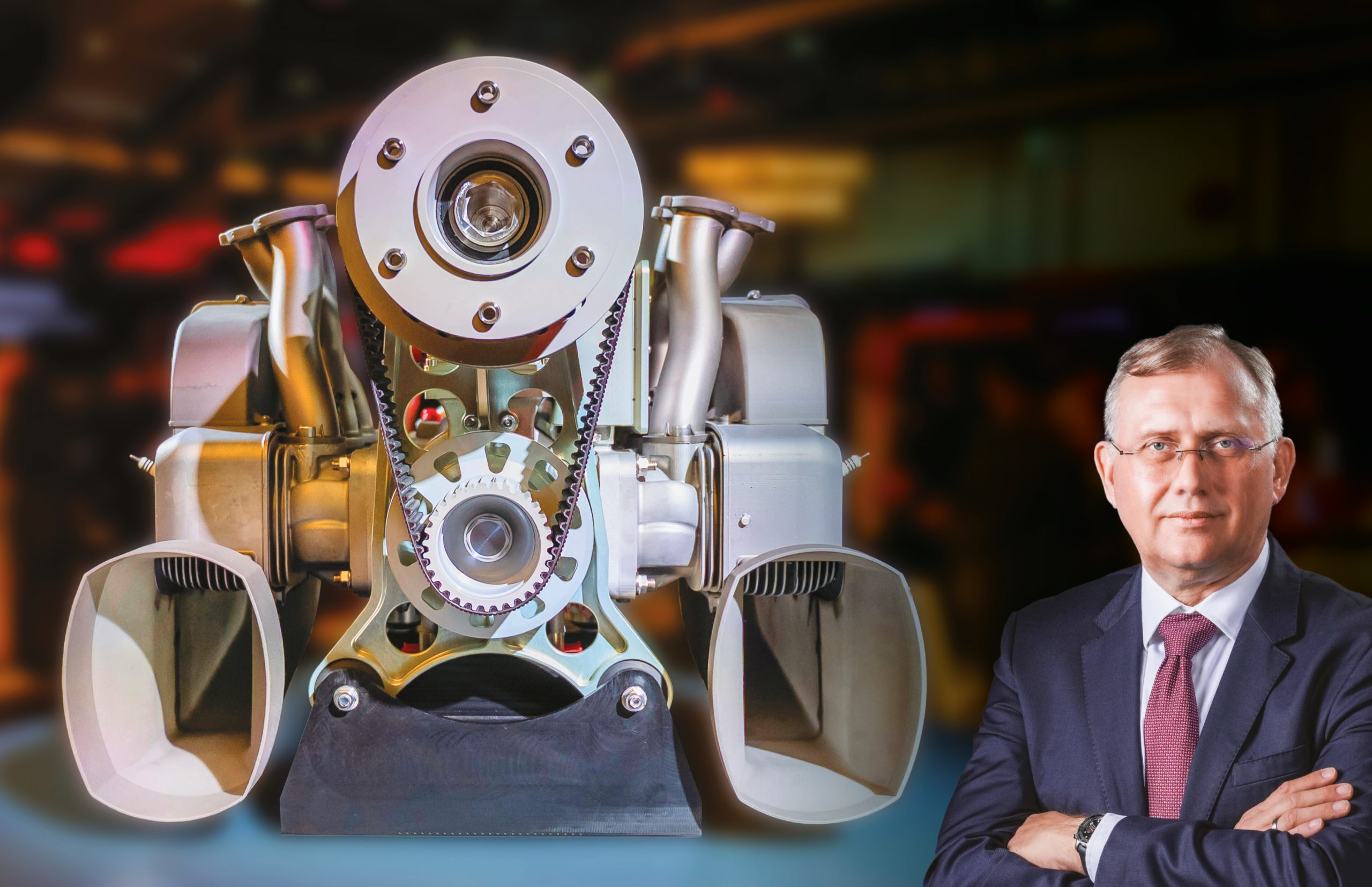

As an integrated propulsion OEM, POWERTECH controls every stage of the system lifecycle, from concept development to system design and engineering, advanced manufacturing, rigorous in-house testing, system integration, and lifecycle support, all within the UAE. We collaborate closely with OEMs and platform developers from the earliest design phases to ensure propulsion requirements are embedded into the system architecture. Our engineering team leverages advanced R&D tools and manufacturing techniques to accelerate design and development cycles and ensure first-time-right outcomes. On the production front, our manufacturing line is equipped with advanced machining and precision manufacturing capabilities, in line with the highest international aerospace and defence quality standards. Our in-house test cells validate engine performance, durability, and reliability under simulated operational conditions, providing critical feedback into our design and manufacturing processes.

System integration is also equally critical. Our solutions are designed to ensure seamless integration with flight control systems, avionics, and payload configurations. This holistic approach positions us not only as an engine supplier but as a strategic propulsion partner capable of delivering ready-to-integrate, multi-mission solutions.

POWERTECH is a relatively new brand under the EDGE umbrella. How are you building market trust, and what have been your biggest achievements since inception?

Building market trust requires credibility, delivery, and proven performance. Since our establishment, POWERTECH has collaborated with partners within EDGE to support the development of sovereign aerial capabilities.

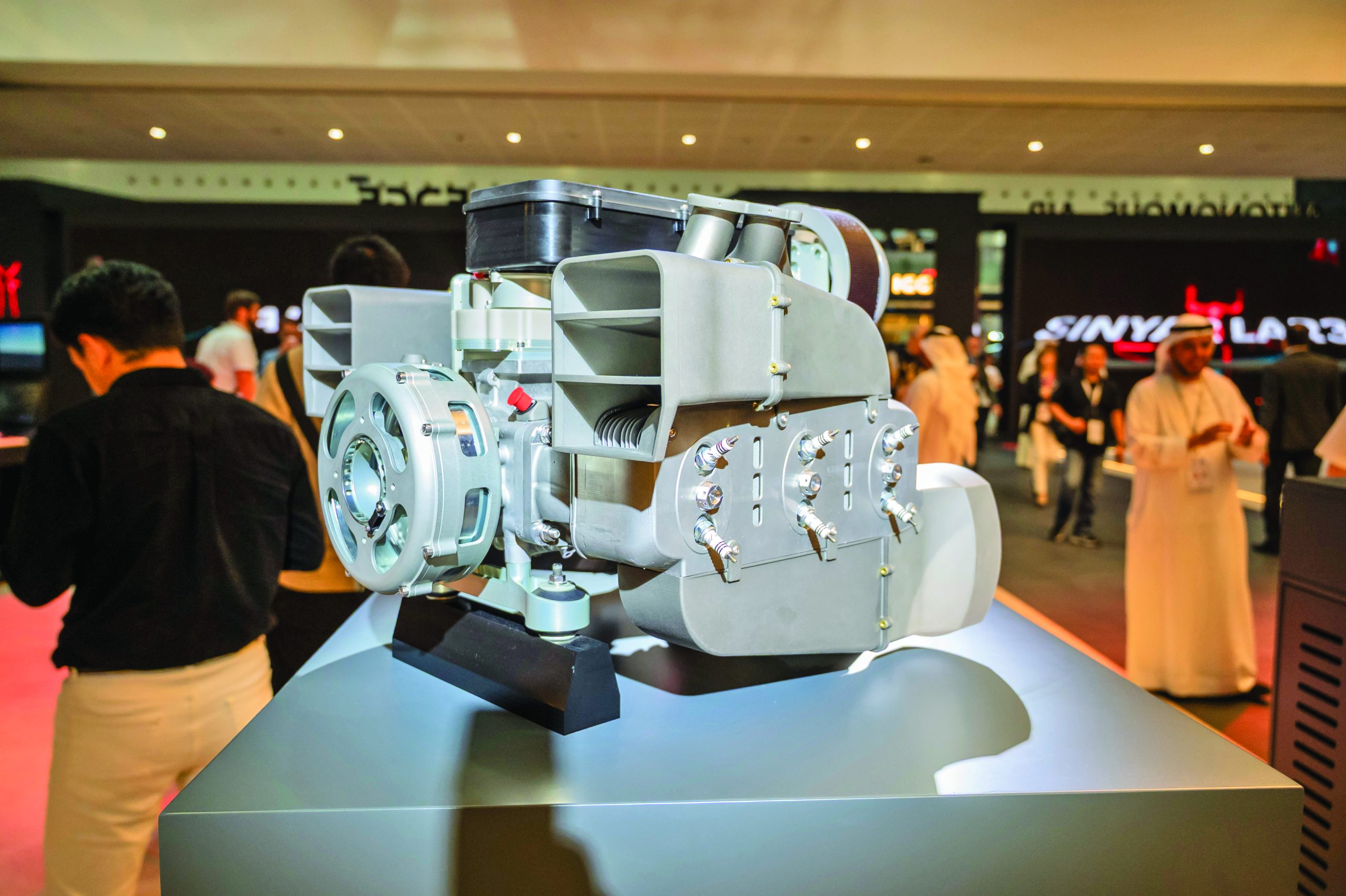

This has driven the launch of our first combustion engine, the P145i, which has since been ordered by ADASI, a strong endorsement of the engine’s performance, reliability, and readiness for operational deployment. Beyond the EDGE ecosystem, we’ve actively engaged with key regional and international stakeholders at leading industry platforms such as IDEX, reinforcing our operational readiness and mature offering on a global stage. On the home front, we’ve invested in building a world-class engineering workforce, robust quality assurance frameworks, and state-of-the-art facilities to ensure long-term growth, delivery assurance, and alignment with global aerospace and defence manufacturing standards.

While we are still early in our journey, these foundations are positioning POWERTECH as a trusted and capable propulsion partner for international customers and industry partners.

How does POWERTECH strike a balance between delivering purpose-built, high-performance systems that are also scalable and modular across different platforms and mission profiles?

Scalability and modularity are embedded into every propulsion system we build. By designing propulsion solutions tailored to specific operational requirements, we ensure faster responsiveness to diverse mission profiles and evolving customer needs. Our propulsion systems are designed for seamless adaptability across a wide range of aerial platforms, from compact tactical UAVs and medium-range ISR systems to larger, more complex UAVs. This approach not only reduces time-to-market and supports integration across multiple platforms but also drives commonality across customer fleets, ultimately streamlining maintenance and reducing through-life costs. Scalability is not a trade-off; it’s a requirement, particularly in integrated defence ecosystems, where interoperability and mission flexibility are key priorities. Modularity, meanwhile, enables long-term sustainment and future-proof upgrades. By delivering fit-for-purpose, mission-ready propulsion solutions, we empower our customers to maintain an operational edge without the burden of costly redesigns or platform overhauls.

Testing and validation are critical to ensuring mission-readiness. How does POWERTECH ensure reliability and performance across different operational conditions, and what role do your in-house capabilities play in this?

Reliability is central to propulsion system performance, particularly in unmanned systems, where engine failure can compromise not just platform survivability but also the mission.

At POWERTECH, we have developed a fully equipped in-house propulsion test facility capable of executing performance, endurance, and environmental stress testing. These include sea-level static performance tests for turbojets and turbofans up to 10 kN. These tests are conducted to international aerospace and defence standards, ensuring our engines meet or exceed the stringent benchmarks required for operational deployment. By maintaining full control over the testing ecosystem, we are able to fine-tune our systems during development, ensure consistency in quality, and meet rigorous performance and durability standards.

This enables us to accelerate development cycles and deliver propulsion systems that are mission-ready from day one. In parallel, we work closely with platform OEMs to address integration challenges and ensure system-level validation, not just engine performance in isolation, further reinforcing our commitment to ensuring operational reliability.

The defence and aerospace sectors are evolving rapidly. What trends are you closely monitoring, and how is POWERTECH adapting its product development strategy to meet emerging operational requirements?

We are actively monitoring several major trends that are shaping the defence, aerospace, and propulsion sectors.

One notable trend is the clear shift towards purpose-built propulsion systems, designed specifically for mission and platform requirements, rather than repurposed solutions from adjacent industries, which often struggle with integration and fall short on performance. There is also a clear emphasis on long-endurance platforms with reduced acoustic signatures, particularly for ISR operations. In parallel, there’s a growing demand for modular, multi-mission UAVs, which require propulsion systems that are not only reliable but also scalable and adaptable without requiring major redesigns.

At POWERTECH, we are working closely with OEMs and system integrators to ensure our engine capabilities align with our customers’ evolving operational needs.

Finally, there is a rising demand for indigenous, export-ready technologies. Our strategy is to develop propulsion systems that address internal mission requirements while adhering to international export standards, supporting EDGE’s broader objectives for global competitiveness and sovereign capability development.

Since its launch, how has POWERTECH contributed to the UAE’s national priorities of industrial localisation, advanced manufacturing, and talent development? Looking ahead, what is your strategic vision for expanding POWERTECH’s role within the regional and global defence ecosystem?

POWERTECH was established to serve as a national centre of excellence for propulsion systems, and we take that role seriously. From the outset, we have prioritised in-country capability development, both in terms of technical infrastructure and human capital.

Our design, manufacturing, and testing operations are all based in the UAE, contributing directly to national targets and helping build a homegrown defence industrial base, all while ensuring sovereign control and local value creation.

On the human capital front, we are investing in creating a specialised, highly skilled workforce that can support and sustain critical propulsion technologies. Looking ahead, our goal is to become the propulsion partner of choice, regionally and globally, supporting not only EDGE entities and regional partners but also global customers seeking reliable, mission-proven propulsion systems.

Ultimately, POWERTECH is not just building engines; we are powering sovereign defence capability, industrial growth, and international competitiveness.

How is POWERTECH expanding its product portfolio to address emerging requirements for high-performance, compact propulsion systems in next-generation unmanned platforms?

POWERTECH is expanding its propulsion solutions portfolio to meet the growing need for compact, high-performance engines in next-generation unmanned platforms by utilising state-of-the-art technologies to keep the engine diameter as small as possible and ensure high performance. These key technologies include, but are not limited to, mixed-flow compressors and plasma ignition for fast start-up times.

Another key advantage of POWERTECH products is that they are purpose-built, meaning that platform requirements are taken into consideration early in the design phase. This includes provision for bleed air to be available for use by the platform.

A key example of this is POWERTECH’s latest turbojet engine, where all the advanced technologies mentioned are utilised to produce a highly compact engine suitable for 300-500 kg unmanned platforms.

This strategy ensures POWERTECH delivers a family of engines that are compact, efficient, and tailored to emerging unmanned system requirements.●

» Interviewed by: «ALJUNDI»